One of our most common transmission in for repair and rebuild we find the Ford Powershift transmission.

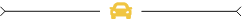

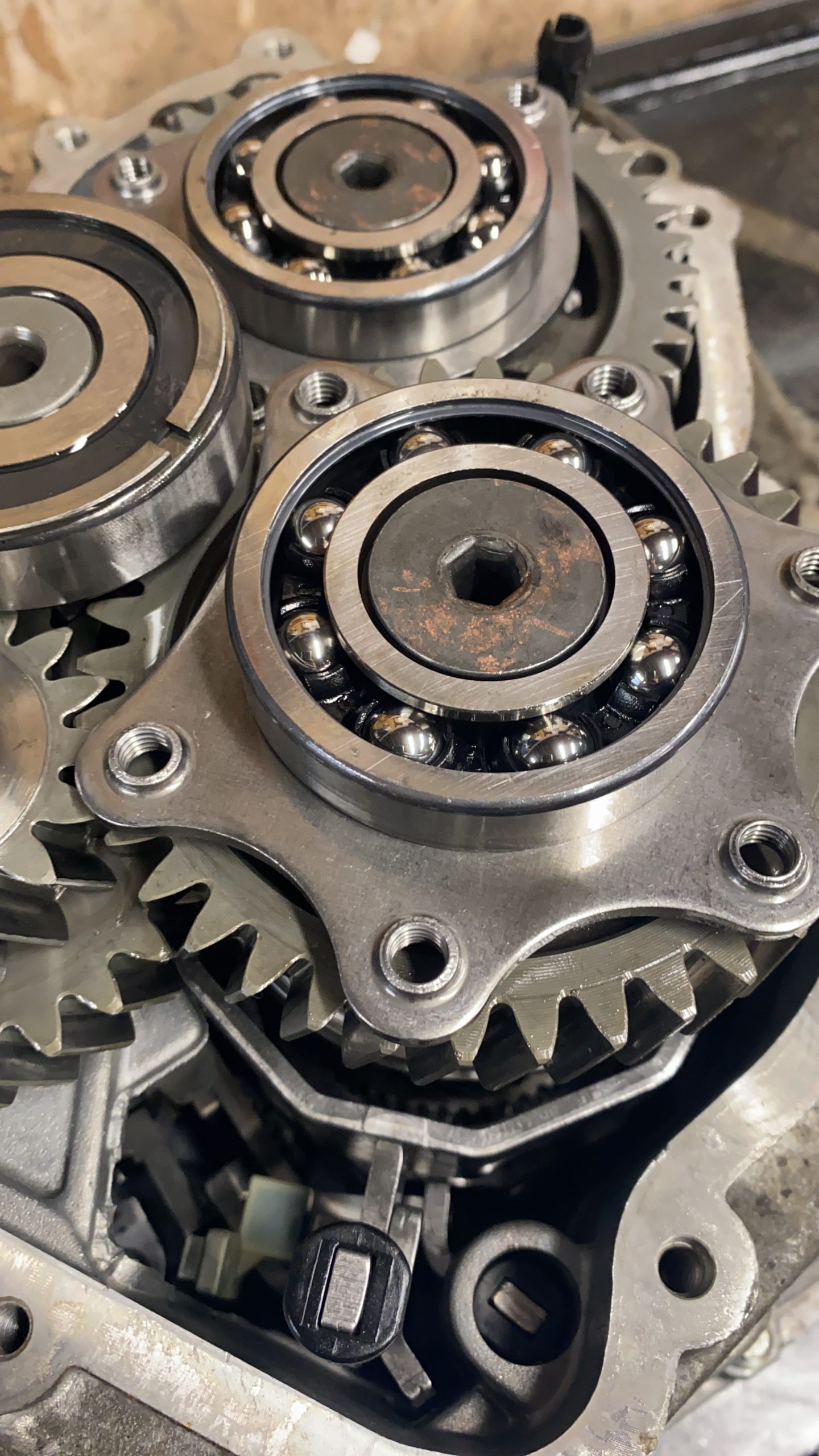

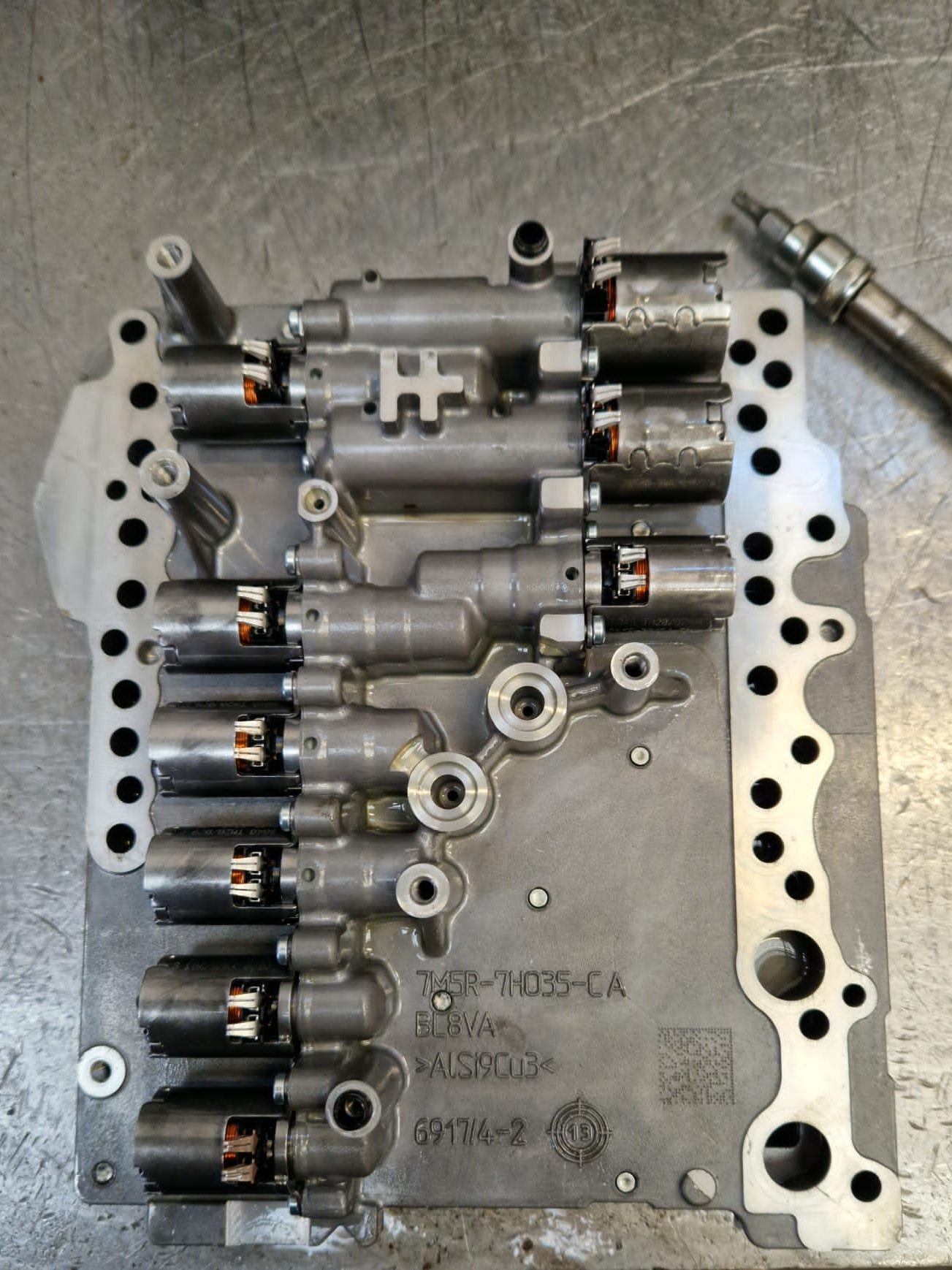

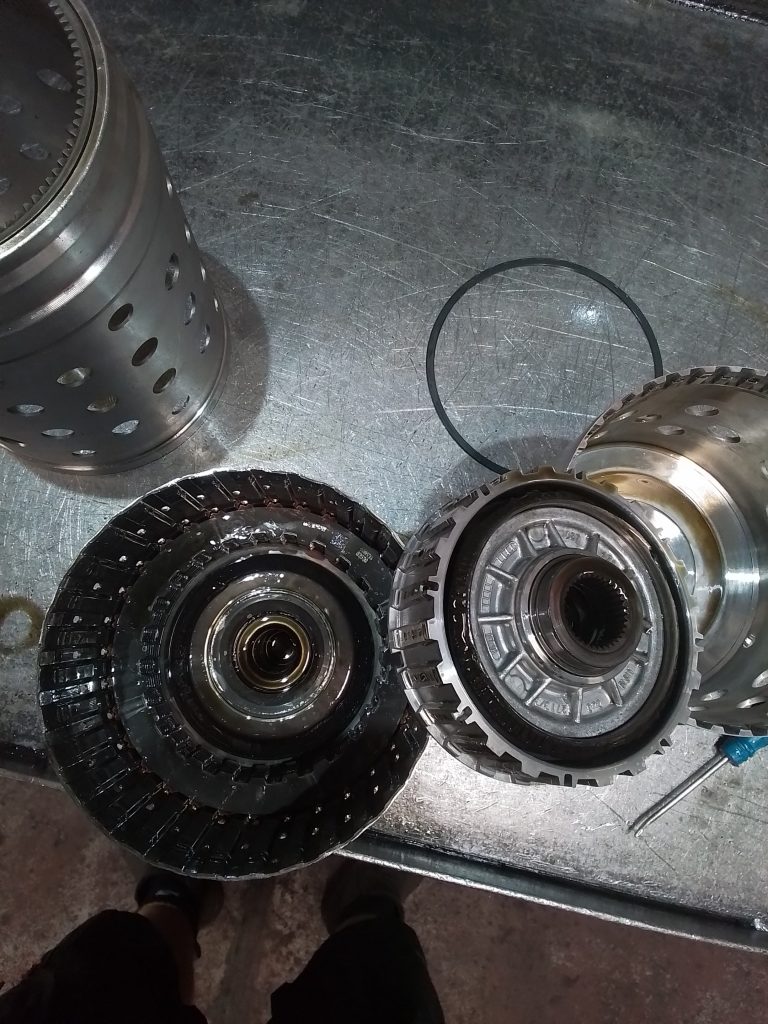

Introduced to the Ford owner in 2008 the ford powershift gearboxes uses two clutches to operate what is effectively a manual transmission designed and built by Getrag, in a joint partnership with Ford. The gearbox was revolutionary in its design and desired application, one clutch would operate the even gears 2-4-6 and one clutch would operate the odd gears 1-3-5 as well as reverse. This meant no downtime from a torque converter or lag from one gear to the next because the transmission could selected the next required gear based on the speed of the vehicle and how hard you are pressing on the accelerator, if you think of them as two separate gearboxes that are working as one. One gearbox houses all the odds with reverse and the other houses all of the evens and depending on the speed of the vehicle one of the clutches will engage and the other will disengage. The valve body (Hydraulics) and the mechatronic unit (Electrics) have a key part to play when ensuring the gearbox is communicating with the other components on the vehicle. For example if the vehicle is revving at a certain RPM and the wheels are turning at a certain speed, the mechatronic is telling the valve body what to perform and the physical gears will know what gear to be in depending on the needs of the vehicle. This is all done within the

click of a finger and unbeknown to the driver!

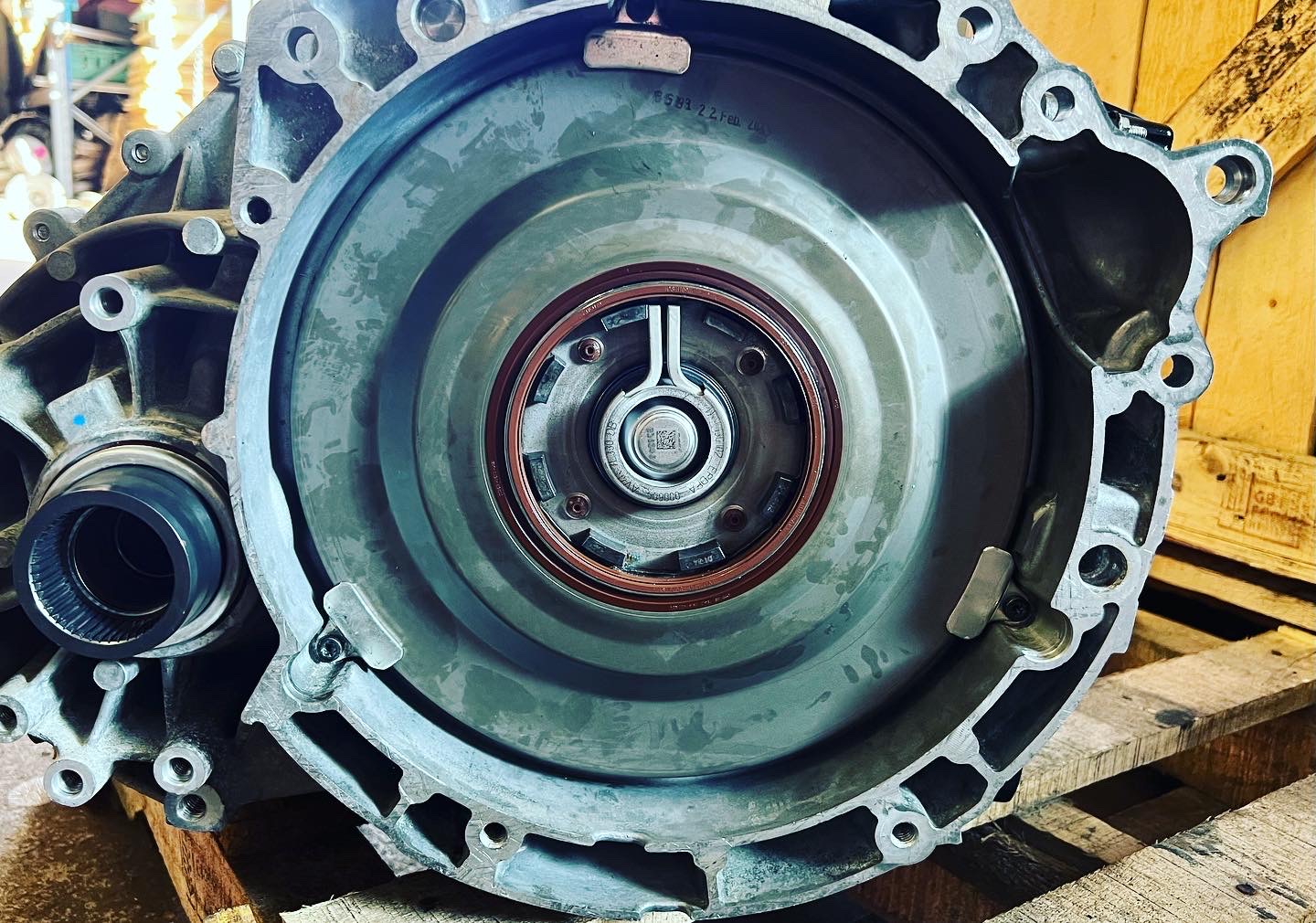

What Ford and Getrag decided to do in their wisdom was to build a Dual Mass Flywheel internal to the gearbox and sit in the exact same oil as the clutches, the gears, the valve body and the mechatronic unit!!

The purpose of a conventional dual mass flywheel is to dampen the vibrations coming from an incredibly hard working engine and to prolong the life of a gearbox, in a normal manual vehicle a dual mass flywheel is a lot more cost effective to replace than a broken transmission due to vibration and distress and is often replaced along side a clutch.

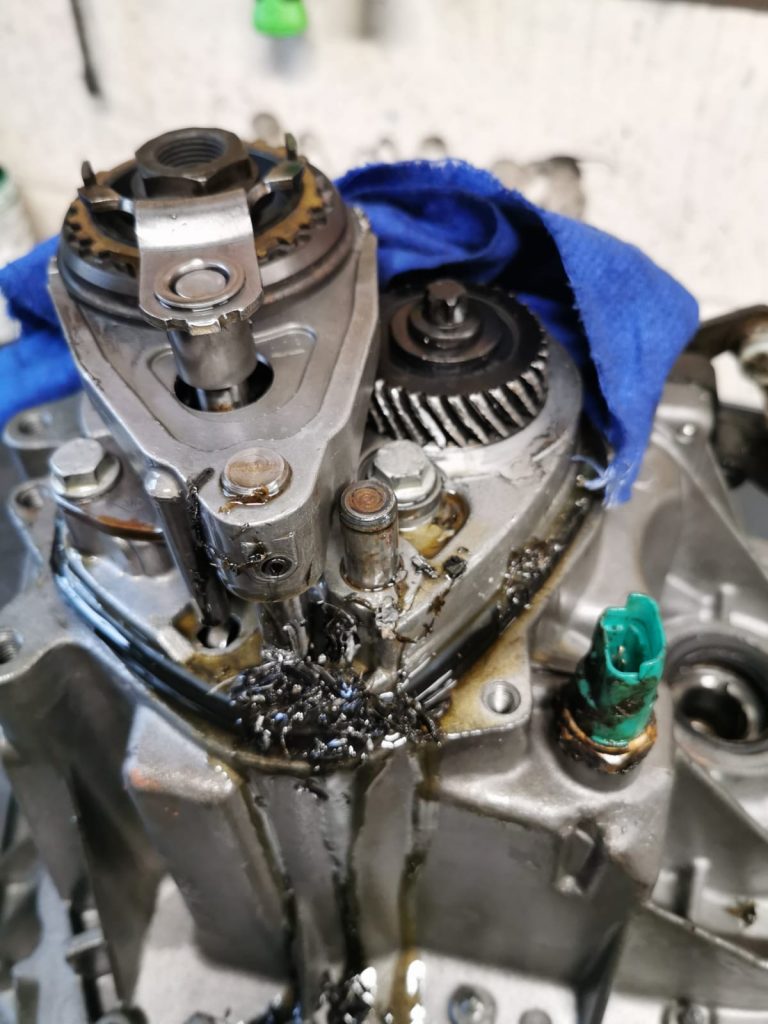

The gearbox has two filters, one that is serviceable on the side of the transmission and one deep inside the gearbox that can only be replaced once the gearbox has been removed and taken apart, the service interval for this item is recommended every three years or 30,000 depending on what one comes first. Now yes, oil changed can prolong the life of your transmission and can improve gearchange but you must keep on top of this to give your gearbox the best chance of survival. Some customers of ours have been very much on top of servicing the gearbox and have still encountered the dreaded transmission failure limp mode light come up on their dash.

How to notice if your gearbox is beginning to play up?

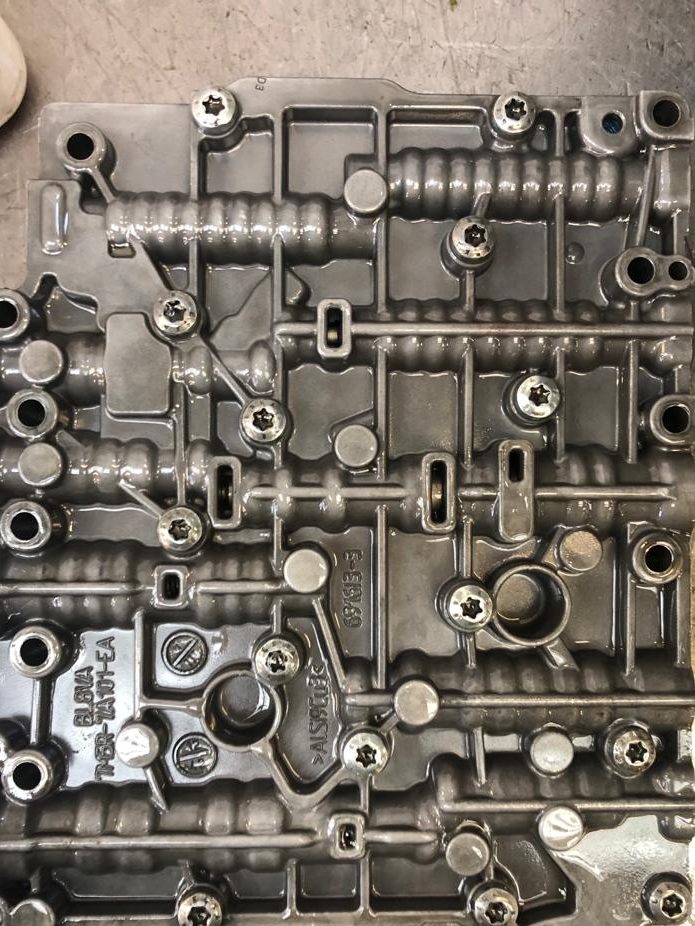

If you are to encounter problems with this particular gearbox, you will face them mostly in the lower gears when the clutches need to be applied smoothly, you will experience a delay into gear, a slight bump or even a big bang depending on the timeline of failure. The worst part of all is that the gearbox can have a complete loss of drive and you will not be able to move, this is down to the filter becoming blocked from the components that make up the Dual Mass Flywheel.

When the oil filter is blocked the oil pump cannot perform correctly and the gearbox is starved of oil.

You may also lose reverse, this doesn’t mean exactly that you have an issue with reverse gear but it means that the vehicles brain has identified a problem and to limit the damage it will reduce function.

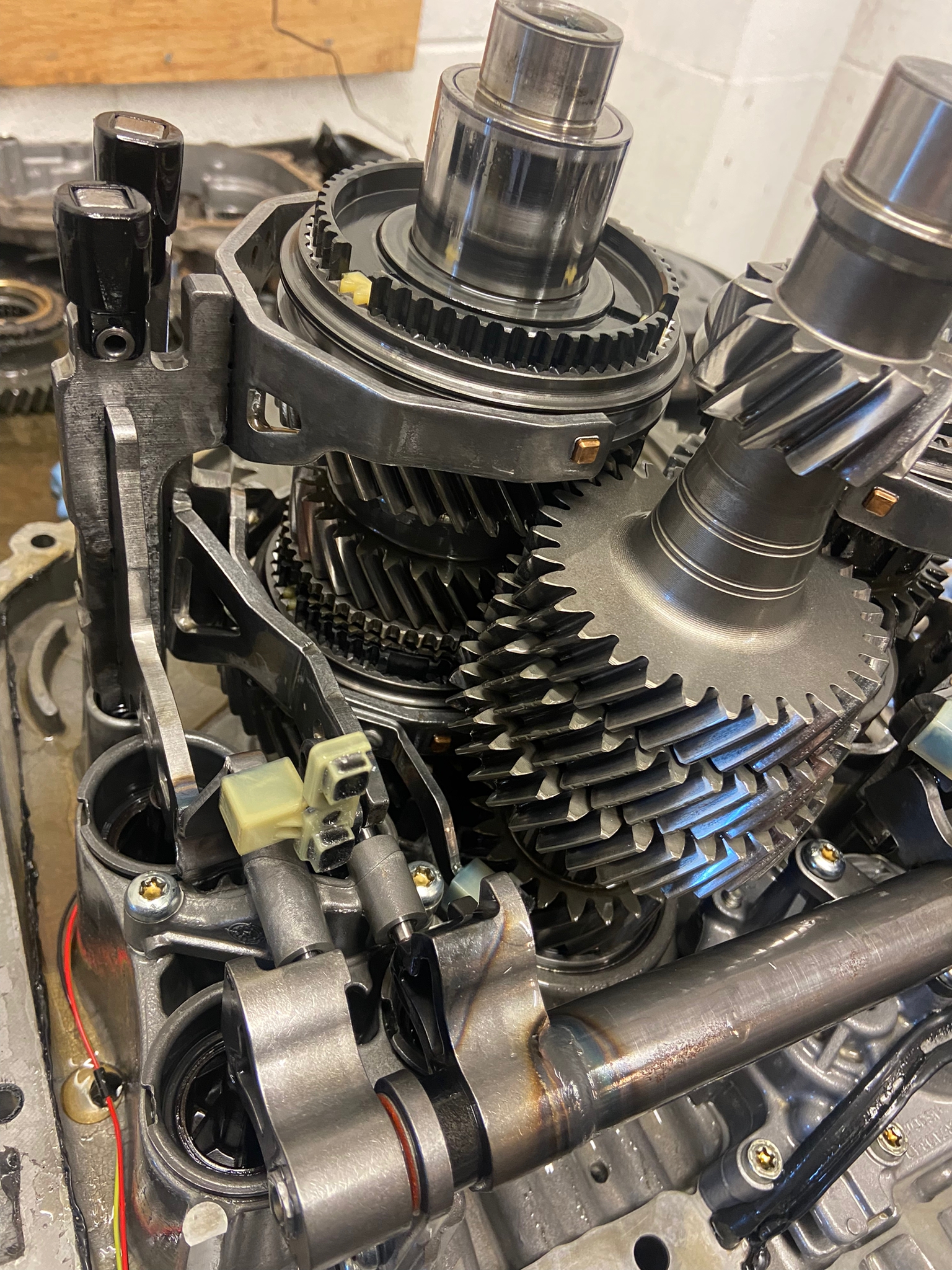

At The Gearbox Centre we build a large amount of these gearboxes on a weekly basis and invested heavily into diagnostic and testing equipment, this enables us to identify what has caused the gearbox to fail and how to rectify the issue and reverse engineer the problem so we can aim to keep your vehicle on the road for as long as possible.

If you have any questions about the powershift gearbox then please feel free to contact us.

POWERSHIFT GALLERY